Welcome to sia stones

Welcome to Sia Stones, the leading manufacturer and exporter of Tiles, Slabs and Countertop in Onyx, Marble, Travertine, Sandstone, Quartz, Agate and Semi-Precious Gemstones. With over 20 years of experience in the natural stone industry, We offer a wide range of luxury natural stone slabs for residential and commercial projects, such as countertops, flooring, wall cladding, backsplashes, backlit panels, furniture, and more.

At Sia Stones, we are committed to providing our customers with the highest quality natural stone products at competitive prices. We source our materials from the best quarries worldwide and use advanced technology and skilled craftsmanship to produce stunning slabs and tiles that meet international standards. We also offer customized solutions to suit your specific luxury interior design preferences.

Whether looking for a classic or contemporary look, Sia Stones has the perfect natural stone product. Please browse our online catalogue to see our fantastic collection of Onyx, Marble, Travertine, Sandstone, Quartz, Agate and Semi-Precious Gemstones in a variety of patterns and finishes. We ship our products globally and ensure safe and timely delivery.

OUR STONES

Welcome to our world of exquisite natural stone designs, where luxury meets functionality and timeless elegance. Our passion lies in bringing the beauty and sophistication of semi-precious gemstones and natural materials to modern living spaces. We craft breathtaking pieces that redefine interior design, from countertops to furniture and tiles.

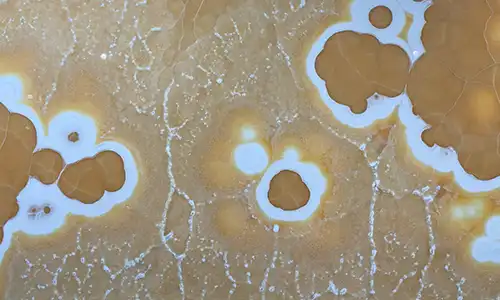

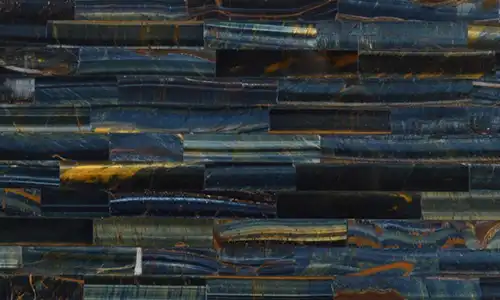

Unveiling the Timeless Elegance of Onyx in Modern Design

Discover the unparalleled beauty of onyx as we showcase its timeless elegance and versatility in modern design. Our expertly crafted onyx pieces add a touch of luxury and sophistication while creating breathtaking focal points in any space.

MOST POPULAR ONYX

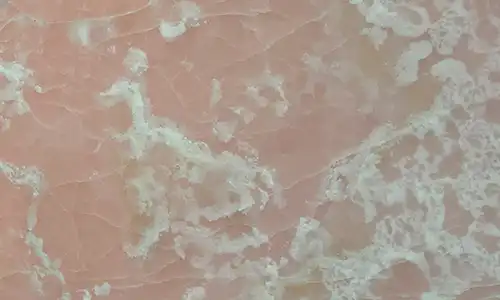

From Quarry to Home: The Fascinating Journey of Marble Slabs

Embark on a journey with us as we explore the fascinating process of transforming raw marble slabs from the quarry into stunning works of art for your home. Learn about the intricate craftsmanship and artistry that goes into each unique piece.

BEST IN CLASS MARBLE

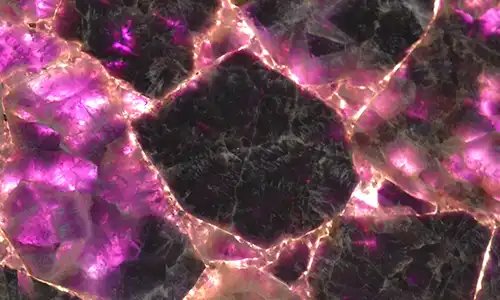

LAVISH COLLECTION IN SEMI-PRECIOUS GEMSTONE

TOP TRENDING BACKLIT STONES

Seamless Global Delivery

we understand that your vision for your space transcends borders. That’s why we offer convenient doorstep delivery of our exquisite tiles, slabs, and countertops directly to your international location.

Choose from Cost-Effective Sea Cargo or Expedited Air Cargo

Sea Cargo: Ideal for budget-conscious projects, with extended delivery timelines that keep costs manageable.

Air Cargo: Perfect for time-sensitive projects, ensuring swift delivery to meet your deadlines no matter where you are.

OUR LOGISTICS AND DELIVERY PARTNERS

FROM THE BLOG

Most Expensive Natural Gemstone Slab and Surface For Upscale Lavish Interiors

Have you ever wondered what are the most expensive natural gemstone slabs and surfaces that [...]

Jewel-Toned Slab In Semi-Precious Gemstone Using Golden Infusion

Have you ever wondered how to add a touch of glamour and sophistication to your [...]

Blue Agate Hotel Interior

Blue Agate Hotel Interior Dei Martiri Suite Naples Italy Beautiful crystal blue agate slabs used [...]

Black Color Tone slab and surface in Natural Onyx, Agate and Gemstone

In the realm of interior design, the choice of materials can significantly influence the ambiance [...]

STONE SAMPLES

Buy stone tile samples to check quality of our material.

High-Quality Gemstone Slabs

Indulge in the exquisite beauty of our premium gemstone slabs.

Ethically Sourced Stone

Sustainable luxury: Explore our collection of ethically sourced stone for a guilt-free statement piece.

Certificate of Authentic Stone

Experience peace of mind with a certificate of authenticity for your natural stone purchase.

High-End Backlit Natural Stones

Elevate your space with the mesmerizing glow of our high-end backlit natural stones.

Backlit Countertop Stone

Transform your kitchen into a luminous masterpiece with our stunning backlit countertop stones.

Luxury Backsplash

Create a breathtaking focal point with a one-of-a-kind luxury backsplash crafted from onyx, agate and gemstones.

Bespoke Luxury Furniture

Craft your dream space with our bespoke luxury furniture designed and tailored to your specifications.

Pre-Fabricated Countertops

Experience the ease and efficiency of pre-fabricated ones without compromising style or quality.

Modern Luxury Interior

Elevate your home to a haven of contemporary luxury with our exquisite collection of natural stone elements.

Healing Gemstone Furniture and Countertops

Embrace the wellness benefits of natural gemstones with our handcrafted furniture and countertops.

Highly Searched On Sia Stones : Blue Agate Countertop | Agate Slab Countertop | Semi-Precious Stone Countertop | White Agate Countertop | Black Agate Countertop | Blue Onyx Backlit | Onyx Slab for Interior | Imported Marble Slab | Prexury Cosentino Collection

Beautiful Agate: Large Size Agate Countertop | Green Onyx Agate Translucent Tiles | White Agate With Gold | Blue Agate Island Top

Exclusive Onyx: Blue Onyx Slab | Honey Onyx Interior | Iranian Onyx For Sale | Natural Green Onyx | Natural Pink Onyx

Handcrafted Semi-Precious Gemstone Slab: Malachite Gemstone Countertop | Malachite Gemstone Furniture | High Grade Lapis Lazuli | Original Lapis Lazuli for Interior | Dark Amethyst Stone | Amethyst Countertop Slab | Amazonite Flooring Tiles

Rock Crystal Semi-Precious Quartz: Smokey Quartz Bar Top | Rock Crystal Slab | Crystal Clear Quartz Natural Slab | Pink Quartz for Flooring | Pink Quartz Countertop | Rose Quartz Island Top